With manufacturing getting increasingly competitive and margins reducing, manufacturers are continually looking at ways to improve efficiency and productivity and increase margins. They are being forced to abandon 20th-century approaches and evaluate new technologies for manufacturing, especially production planning, shop floor scheduling and planning management. Applying a number of the newer technologies with their already established methodologies and practices can lead to significant improvements in costs, productivity and efficiencies, while reducing waste in their processes like manufacturing errors and unplanned downtime.

The manufacturing technology changes

Some manufacturers have been using technology to send data to the shop floor, and process data received from the shop floor. Unfortunately, in most cases the value of that data has not been exploited properly due to technology incompatibilities. In other words, the solutions would do what was expected of them, but the technologies were unable to collate the data resulting in islands of information. This was the situation with older Manufacturing Execution Systems (MES) which could not integrate data from multiple different sources and aggregate it in real-time for analysis and up-to-date decision-making. The MES solutions have now evolved and expanded into the Manufacturing Operations Management (MOM) solutions of today which provide the inter-connected systems required for managing the end-to-end manufacturing process. These MOM solutions also encourage the breaking down of siloes that exist between departments by focusing all parties on optimizing operations which requires collation of data and collaborative solutions. It uses a manufacturing lifecycle approach that integrates the core manufacturing activities (schedule, publish, collect, track, analyze and improve) and teams while allowing them to be viewed from within a single platform.

The methodologies and practices

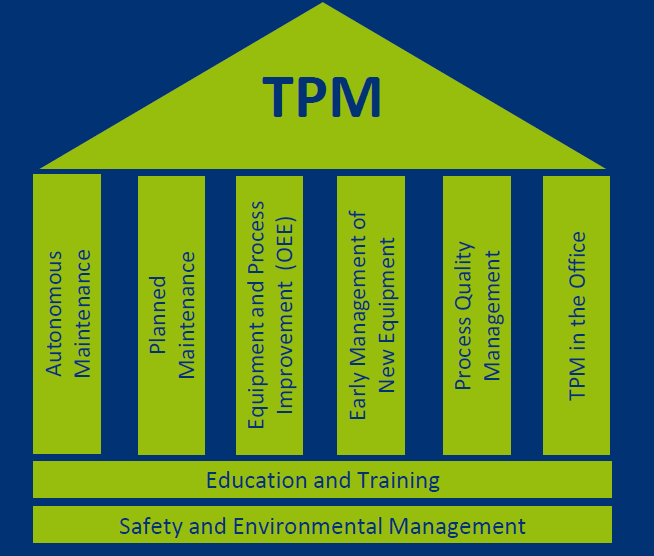

Changing technology will not be good enough. Manufacturers need to apply an understanding of existing and accepted manufacturing methodologies and practices and use the technology to support their own initiatives. For example, Total Productive Maintenance (TPM) strives to achieve perfect production with no breakdowns or other machine-related problems that affect throughput by using a holistic approach to equipment maintenance. While it addresses the most fundamental of manufacturing challenges, it ranges beyond pure factory floor issues and looks at management of the manufacturing process and its supporting functions. There are also other improvement methodologies like Six Sigma which look to understand what affects manufacturing output and improve upon it.

Focusing on TPM, we can immediately see that the process requires support from the various functions and specialists within any business. It looks to drive Continuous Improvement in any manufacturing business and starts with the manufacturing process.

The “20 Keys to Workplace Improvement” by Professor Koboyashi is similar yet more inclusive of the secondary processes. In any of these processes, the initiative requires an initial investigation into manufacturing processes to rank the various areas. Generally, the worst area will receive the initial focus.

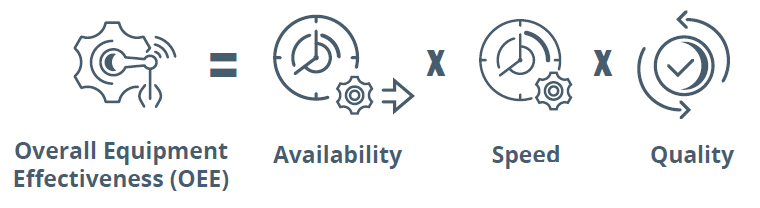

The “20 Keys” methodology allows the business to rate itself from Level 1 to Level 5 on each key. The TPM methodology focusses on measuring how effectively we utilize our machines and measures Overall Equipment Effectiveness (OEE). The success of the TPM initiative is gauged by how much the OEE improves.

OEE is a metric that measures how well a machine is being used (uptime), the speed of the machine against design speed (speed) and the quality of the production. OEE is impacted by downtime losses, speed losses and quality losses.

OEE supports TPM-based initiatives by measuring progress towards “perfect production”.

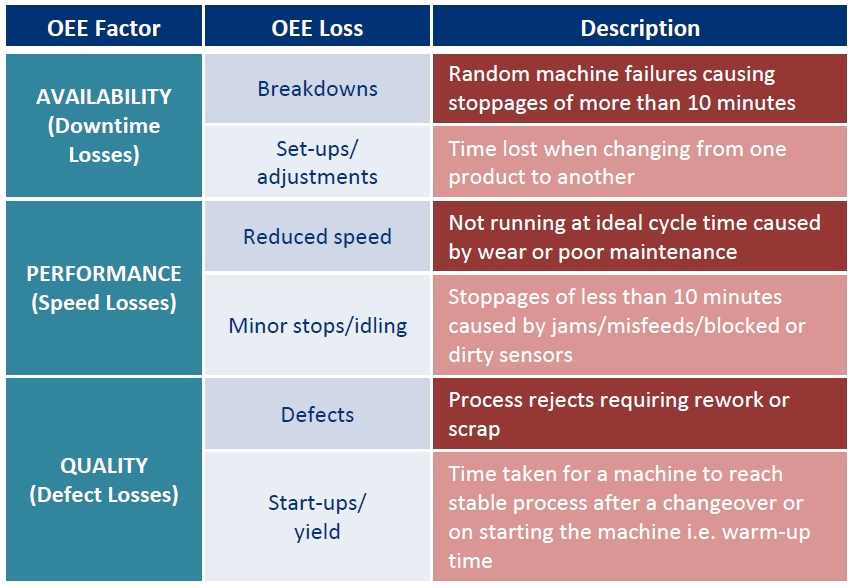

The Six Big Losses

The backbone to improving OEE is identifying and reducing the Six Big Losses (in manufacturing) which relate equipment utilization and factory processes to manufacturing losses and waste. The Six Big Losses and their effect on OEE are summarized in the table below.

Tackling the Six Big Losses with MOM

A good place to start is to focus on downtime. Most factories treat the machines and manufacturing function as a cost center with recovery rates for items produced. This requires the machines to produce as many saleable items as possible to maximize recoveries. The concept of “Sweat the Assets” comes into play here – not abusing the machines and under maintaining them, but to make every item a good one. This is where a MOM system solution can make a significant contribution:

1. Publish an accurate plan.

2. Measure whether the plan was achieved or not.

3. Collect information on the amount of downtime experienced.

4. Understand the reasons for the downtime by studying the reason codes.

5. Look at the speed of machine operation.

6. Count all of the defects manufactured.

7. Analyse them for likely causes and address those causes.

Poor maintenance has been identified as one of the highest contributors to defective item manufacture. Stop-Start manufacture has been measured to be responsible for 30% of all defects manufactured – most of the defects are manufactured on start up after a stop. Therefore, try and only stop the machine for a changeover.

The MOM solution can be used to monitor machine status, create reason codes for stoppages and allocate all downtime to predefined categories. These can then be investigated and the causes of the downtime rectified.

It should be noted that each element of downtime is additive, meaning that while each stop may be a small amount of time, it can quickly add up to a major loss.

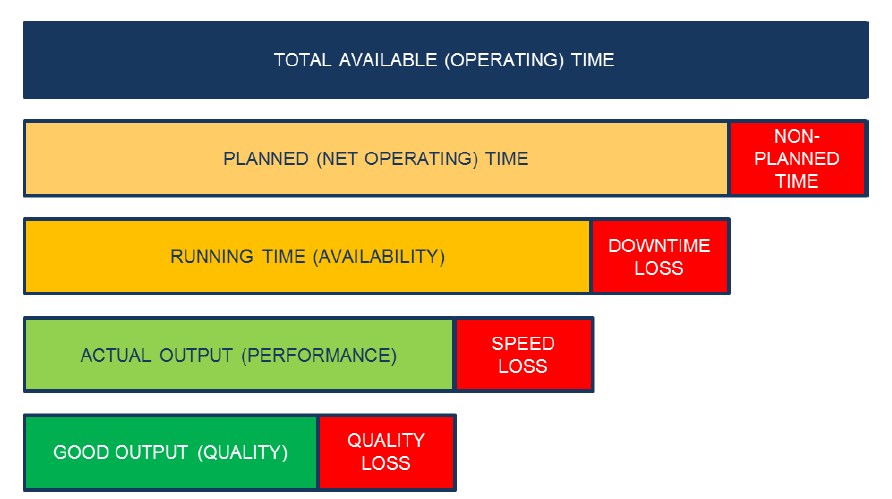

As can be seen from the diagram below, the total productive time on the machine can very easily become a small portion of the total available machine time scheduled for manufacture.

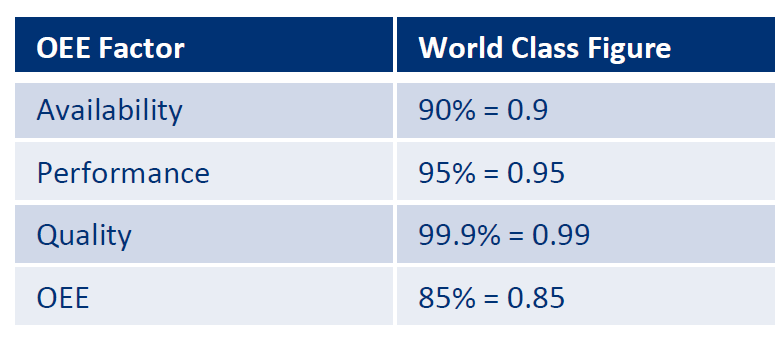

Before any initiatives have been implemented, an OEE of 40% or less, is not uncommon. A score of 60% is fairly typical for discrete manufacturers who have some initiatives in place. An OEE of above 85% is considered to be world-class. To achieve that, all factors need to be meeting the minimum values in the table below.

Note – the OEE is only measured on the bottleneck equipment. Any other machine will have standing time while waiting for the bottleneck.

Once an OEE baseline level has been established, the focus should be on a continual improvement program for the plant. The OEE metrics will measure the success of the program, but often we find outside issues affecting plant performance. Ultimately, the business will need to focus on creating specific improvement projects which address each of the OEE components: Availability, Performance and Quality. More importantly though, by measuring the key components and investigating their sub-standard performance will lead to identifying the drivers of the poor performance and projects to address these.

|

Increase productivity, minimize loss, lower production costs with SYSPRO MOM“If you can’t measure it, you can’t improve it…to increase your productivity and lower production costs you need to benchmark your performance and minimize loss within your manufacturing process.” |

1 thought on “Applying established practices with MOM to improve production”